岩芯分析

The fat and oil content of foods is always a critical factor as following a healthy diet becomes increasingly important to consumers. This means manufacturers need to ensure the accurate, fast and clean measurement of fats and oils in a variety of foods, not least those enemies of the strict diet: snacks and chocolate. Moreover, the presence of oil is a major determinant in texture, mouthfeel, flavour and quality – therefore it is vital to ensure consistency across the production process. Nuclear Magnetic Resonance (NMR) can help in this objective with a rapid, simple and precise method for the measurement of fats and oils.

Careful control of oils and fats in snack food is essential in ensuring product consistency in the global snack food industry, one of the fastest growing segments in foods today. It is a highly competitive industry where success requires high quality and, above all, a consistent product to ensure repeat consumption. Likewise, in the chocolate sector, its enduring consumer appeal rests on quality and consistency. Therefore, it is essential to quantify the fat content during processing for end-product consistency.

Simpler, faster, more flexible

Traditionally, quantifying the fat content would mean using solvent extraction which takes 2-3 hours to obtain a result so would not be compatible with process control. Increasingly, Near-Infra-Red Spectroscopy (NIRS) is being used both on- and off-line. However, it is very sensitive to physical properties including particle size, colour etc. meaning it requires complicated ‘black box’ calibrations to predict the concentrations. Not only are the calibrations often owned and maintained by the instrument manufacturer, there is also no way of knowing whether the samples measured are represented in the calibration and results given are correct. Time Domain NMR, on the other hand, gives users complete ownership and control of the calibrations, which are simple and linear.

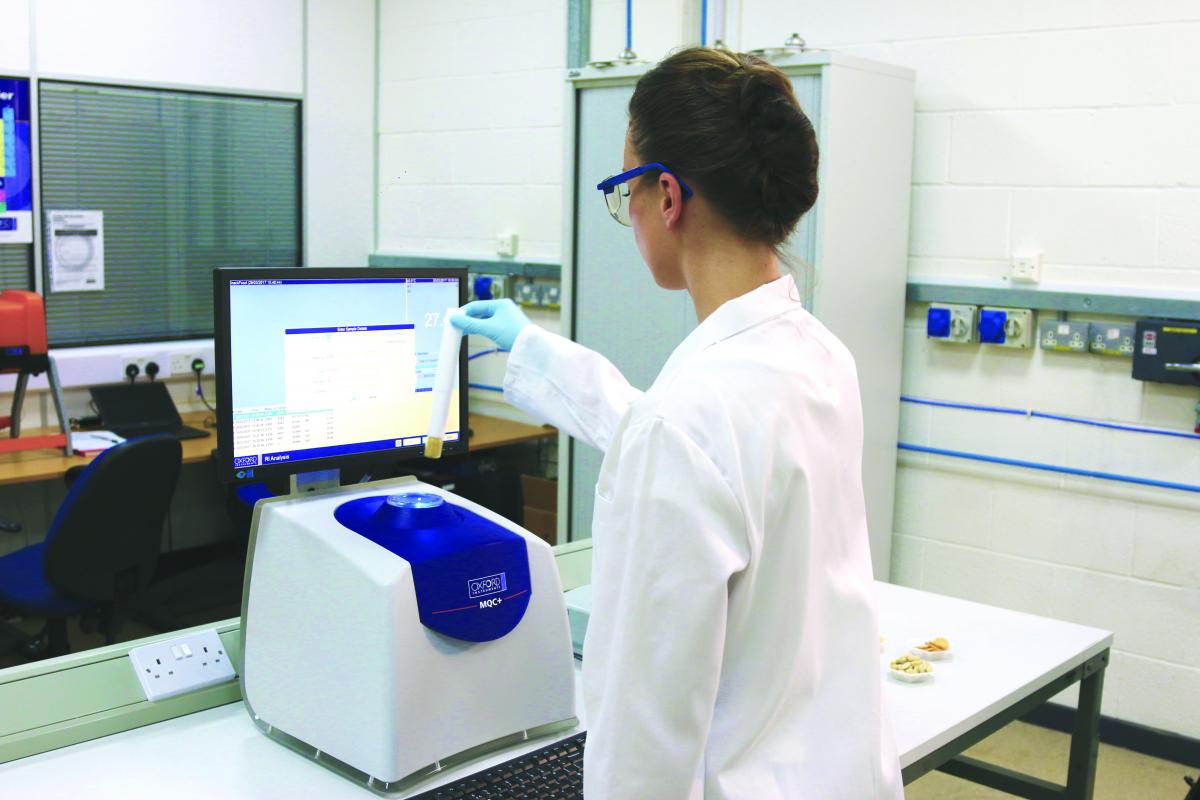

For both snacks and chocolate, our MQC+ benchtop NMR analyser provides fast, accurate and solvent-free measurements that are routinely used for production control in the world’s leading manufacturing plants, in many instances to verify the on-line NIRS results. In addition, NMR does not require the use of solvents, or complicated sample preparation procedures, meaning it can be quickly carried out by most employees with minimal training.

The instrument can also measure fat in milk powder, nutritional formula and food ingredients – basically any low moisture sample – giving manufacturers a versatile, affordable platform for detailed analysis.

An intuitive quality control process for food manufacturers

The underlying analytical technique is based on direct measurements of the NMR response obtained from the fat in food products, normalised by the sample mass. The fat content is quantified by calibrating the NMR signal per gram of sample against concentration determined by a suitable reference technique. In practice, this is a process that takes just a few minutes using an intuitive, user-friendly interface and no dangerous solvents or chemicals.

Determining fatty acid compositions and identifying adulteration

We also manufacture benchtop NMR spectrometers which quantify fatty acid profiles (saturates, monounsaturates, polyunsaturates and omega-3), as well as distinguish between different types of oil/fat for food authentication (e.g. coffee, meat, argan and olive oil). This triglyceride analysis works by analysing the high resolution 60MHz NMR spectrum of an oil or fat sample, either as-is or extracted from a food sample. The total measurement time using our X-Pulse NMR Spectrometer, including sample preparation, is typically less than five minutes for most samples.

Why Oxford Instruments?

NMR is a reliable, rapid and precise method that requires minimal training and is available at an affordable cost, providing traceable analysis of snack food, chocolate and other low moisture foods and ingredients. At Oxford Instruments, we provide solution specific instruments using both Time Domain NMR and NMR spectroscopy with global applications and service support.

Therefore, if you rely on the accurate, fast and affordable analysis of oils and fats in foods, we are ideally placed to support you to optimise development of new products and maximise quality control and yields in manufacturing.

To arrange a demo of the MQC+ or X-Pulse and see for yourself the benefits benchtop NMR can bring, contact us today.

公安机关备案号31010402003473

公安机关备案号31010402003473