岩芯分析

At every stage of the polymer production process, from Research and Development (R&D) through Quality Assurance (QA) to final Quality Control (QC), accurate measurement techniques are required. A growing number of companies are discovering that benchtop Nuclear Magnetic Resonance (NMR) systems offer a cleaner, faster and more cost-effective way to measure both physical properties and chemical composition. Recent instrumentation advances now additionally enable routine reaction monitoring.

Polymeric materials are critical components in almost every industry and application from healthcare (including drug delivery, implant materials and anti-bacterial coatings), through hi-tech construction materials, to energy systems such as organic photovoltaics, fuel cells and batteries.

Traditionally, polymer research relies on lab tests that are time-consuming, require skilled technicians and involve toxic solvents. Such a convoluted testing environment inevitably causes bottlenecks in analysis and can hold up production lines. NMR, on the other hand, offers faster and more reproducible testing methods to assure manufacturers on the quality of their products and improve the economics of polymer manufacturing.

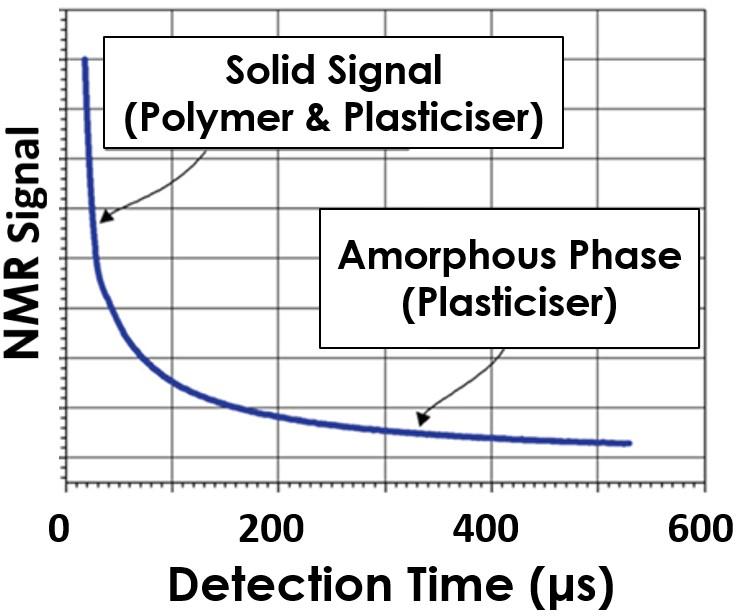

From a Research and Development perspective, scientists require a flexible instrument which allows them to study materials at every stage of production, from the raw materials to the final product. For example, high-performance Time Domain-NMR (TD-NMR) systems are used to measure molecular mobility and diffusion in order to examine the microstructure of samples. These samples must also be measured across a range of temperatures, which is essential for polymer research.

The MQR benchtop analysis system is adaptable to many different measurements and comes complete with user programming and data analysis software. There is also a variable sample temperature option to extend the range of measurements that are possible. It is fast, simple and requires no hazardous chemicals, making it ideal for R&D environments.

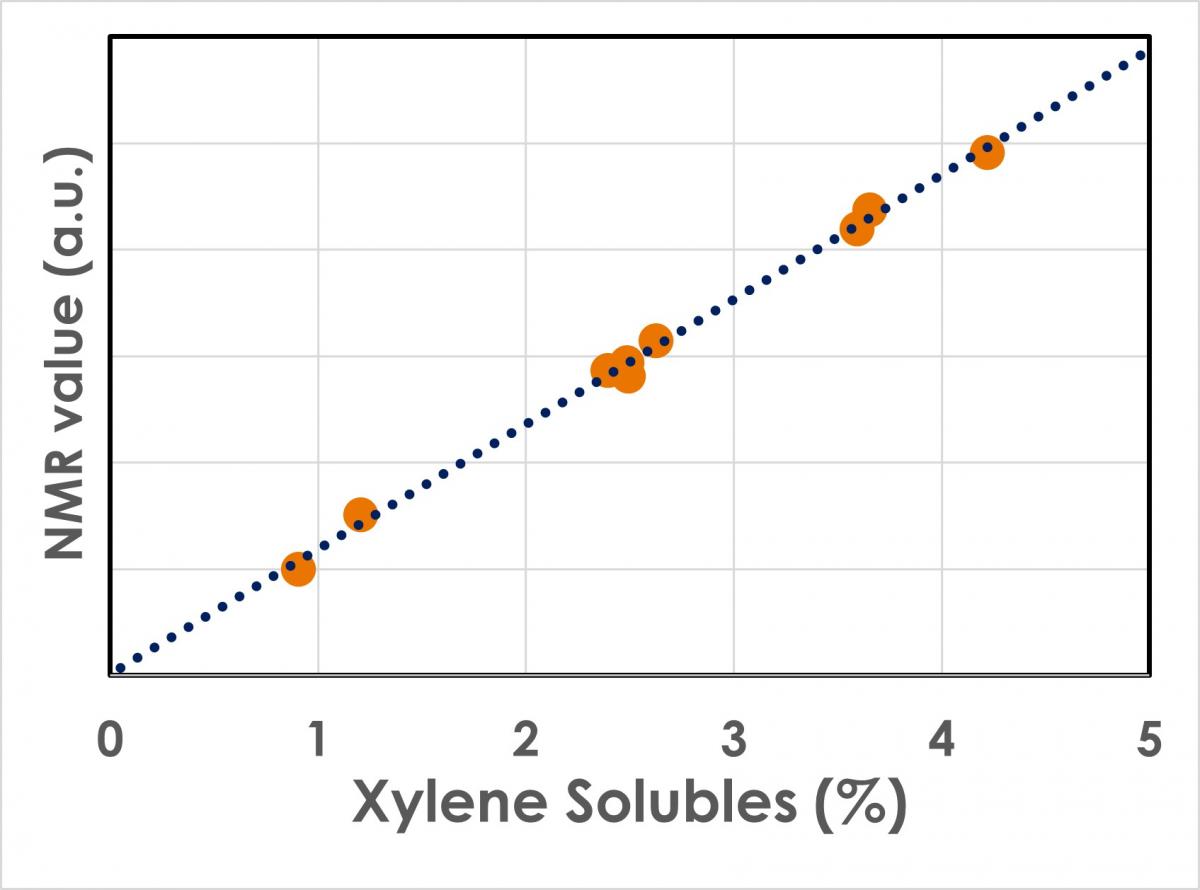

When it comes to Quality Control, the MQC+ benchtop analyser provides measurements of the physical properties of materials such as polymer crystallinity/density and molecular weight. It is easy to use – simply pop a sample in the instrument with minimal preparation and hit the button – results are obtained within minutes.

Its simplicity means that lab assistants need no special skills or training. It also eliminates the need for toxic solvents and, because it is so fast, it removes bottlenecks in production too.

NMR techniques are particularly useful when it comes to understanding the chemical composition of polymers. However, with this type of spectroscopy, companies would typically send samples away to a high-field NMR system. This is unsurprisingly both expensive and time consuming.

That’s why we introduced X-Pulse, a benchtop NMR solution which combines true broadband X-nuclei capability, flow chemistry, reaction monitoring and variable temperature with superior spectral resolution. This enables you to perform a wide range of experiments on the bench in your lab. X-Pulse uses a 60MHz permanent magnet with high homogeneity and temperature stability making it easy to position in a lab and requires no liquid cryogens. X-Pulse may be used with either standard 5mm NMR tubes, or our easy-to-use flow cell.

Not only is it much faster to conduct such analysis in your own lab, it is also more cost effective than using a high-field NMR instrument. It is a perfect combination of convenience, efficiency and cost.

NMR is a clean, fast and reliable method for the analysis of polymers at any stage of their production. We have over three decades experience in building NMR instruments. If you rely on the accurate, fast and affordable analysis of polymers, our range of systems will meet your needs.

公安机关备案号31010402003473

公安机关备案号31010402003473